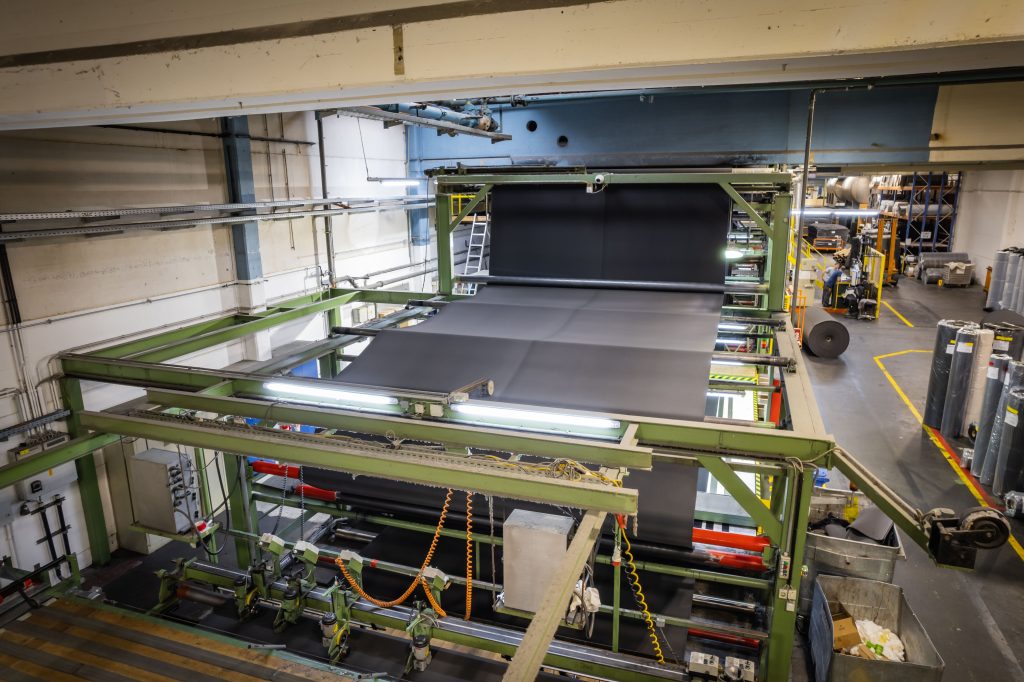

The tufting process is an industrial process for manufacturing textile floor coverings such as carpets. In this process, yarn threads are pierced at high speed through a carrier material, usually a fabric or a film. Special needles move the yarn in a predetermined pattern, creating loops or cut fibres (shorn surface). After the yarn is inserted, the back of the carpet is fixed using a chemical or thermal method to permanently attach the fibres. Tufting is particularly efficient and allows for a wide range of designs, colours and textures, which is why it is one of the most commonly used methods in carpet production.

The dyeing process used at Durmont is called the exhaust method and is a textile dyeing process in which the material is immersed in a dye bath to allow the dyes to be absorbed evenly. The dye bath contains dye, water and additives such as salt or acids that help to fix the dye. By agitating the textile in the dye bath – either by rotating drums, nozzles or mechanical agitation – the dye is distributed evenly and drawn deep into the fibres. Dyeing is done in stages, with temperature and time precisely controlled to achieve optimal results. After dyeing, the material is thoroughly rinsed to remove excess dye, and then fixed and dried.

Drying, especially after dyeing, serves to remove residual moisture from the textiles and to fix the dye. In this process, the textiles are passed through drying units such as stenter frames, cylinder dryers or infrared dryers. Drying is carried out in a controlled manner using heat and air circulation, with temperature, time and humidity precisely regulated to avoid shrinkage or damage to the material. At the same time, the uniform heat distribution ensures that the colour intensity and uniformity are maintained. After drying, the textiles are ready for subsequent processes such as chemical or thermal nap binding.

Shearing is a finishing process in textile production in which the surface of fabrics or carpets is evenly trimmed. In this process, protruding fibres, lint or loops are shortened to a uniform height using rotating blades. This process ensures a smooth, even surface and improves the visual appearance and feel of the material. Shearing is often used on carpets, velvets or velours to achieve a high-quality and consistent texture. After shearing, a cleaning process is usually carried out to remove any cut fibres and prepare the material for the next production step.

Regarding coating, there are currently 2 variants:

1. Chemical Fiber Fixation CFF:

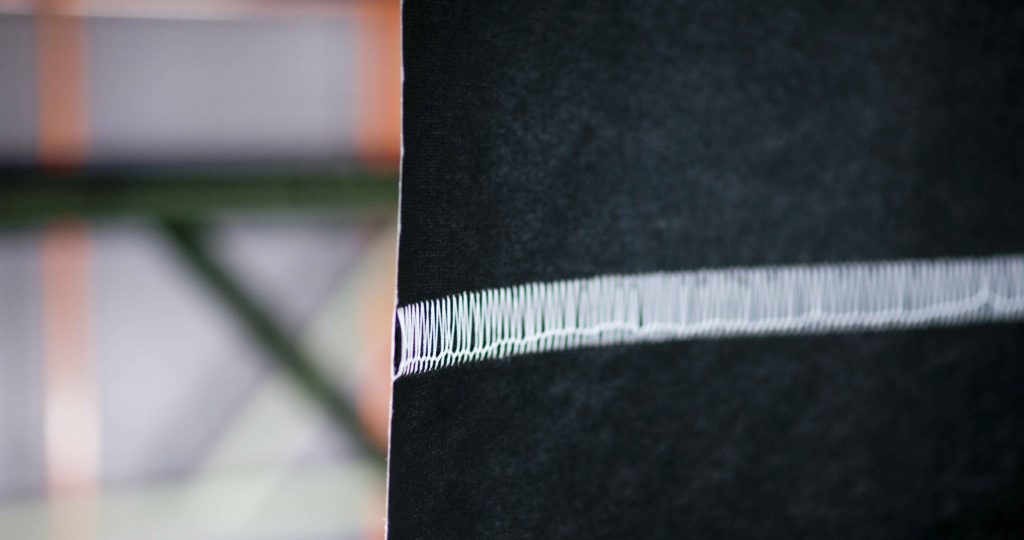

In chemical burl bonding, a coating is applied to the back of a textile, such as a carpet, to bond the burls to the substrate and then to allow further layers of material to be applied. To do this, a liquid polymer, often latex or another adhesive, is evenly applied to the surface. The chemical bond is formed when the coating is fixed by chemical reactions (such as polymerisation) or the evaporation of solvents. The result is a durable, flexible nub structure that provides both adhesion and comfort.

2. Thermo Fiber Fixation TFF:

In the thermal process, the material is bonded to the backing material by heating the piles. Additional layers of material can then be applied to influence the mechanical properties of the carpet. This method is particularly suitable for materials where high strength and durability of the piles are required.

Carpet roll cutting is a precise cutting process in which rolls are cut into smaller specific formats. This is done using a sharp, rotating blade or a special cutting plate that works exactly along the specified cutting lines. The rolls are positioned on a conveyor belt or a cradle to remain stable during cutting and ensure a consistent result. This process makes it possible to cut carpets into different lengths, depending on the requirements of the end product or customer. After cutting, the carpets are inspected, rolled up and prepared for further shipment or processing.